Author: Raymer Engineering Corporation | Published on : 30 Oct 2021

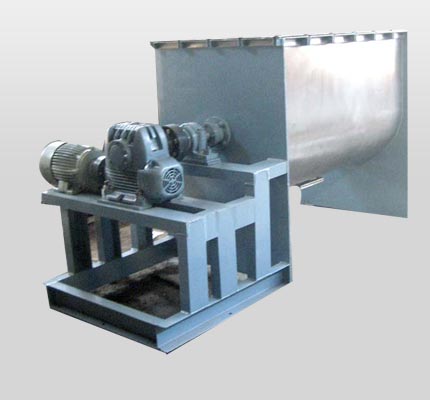

Ribbon Blender Mixer Supplier

Raymer Engineering is one of the leading manufacturer, supplier, and exporter of Ribbon Blender Mixer, Ribbon Blender in India. These machines are manufactured from high-quality materials that are sourced from trusted and reliable vendors. Ribbon Blender Mixers are manufactured at our premises using quality tested components in compliance with industry quality standards.

In a Ribbon Blender Mixer, the dry material gets sufficient continuous movement due to the shape & movement of the ribbon & shape of the container. The total mixing time and RPM required is very less in Ribbon Blender. The powder moves from center to the end of the container and from the end of the container to the center of the container.

Ribbon Blender Mixer unit consists of one worm reduction gear, one electrical motor, belt drive between motor and gear, couple drive between gear to (ribbon) mixing stirrer. Container having four legs with discharge valve & top cover. Both ends of the mixing shaft are sealed with bush & PTFE gland housing & safety guards are provided on all moving parts.

Raymer Engineering’s Ribbon Blender Mixer are used in processing paints, enamel, inks, cement primers and emulsions. Apart from this, our Ribbon Blender Mixer is utilized for processing a wide variety of products.

Ribbon Blender Mixer Advantages / Features

- Ribbon Blender made out of SS304/SS316 or SS316L quality material.

- Available in 500 Litres & bigger model of Ribbon Blenders.

- 3 phase indication facility with D.O.L. starter for on-off operation of motor.

- Inching facility for stirrer for discharge of blending material.

- Limit switch given at top cover for safety purpose.

- Full cover on top side of the container.

- If confirm with order, discharge height must be adjusted,

- Ampere meter to denote load of motor in ampere.

- Operating panel given for safe operation of Ribbon Blender.

- Inching push button provided with selector switch for inching operation during discharge of material.

- Centrally located material Discharge valve. (Butterfly / Sliding Valve)

- Emergency stop panel with Digital timer for batch time setting.

- Dust proof top cover with window provided.

- Easy to install and works efficiently.

- Small occupation area low investment cost.

- Low operation cost and long service life.

- Good final product quality and easy to maintain.

- Environmentally friendly and high classifying capacity.

- Can be manufactured as per Client specifications.

Order the products your company requires, Contact Raymer Engineering Corporation at +91 – 9820544120 or Submit Enquiry Form. For more information on any of our high quality products and Get Quotes within hours.

Working/ Operating Principle of Ribbon Blender Mixer

Ribbon Blender Mixer is primarily combined with a mixing barrel, driven unit, and agitator. Untwist double ribbon is swirled with the main shaft in the U shape barrel with outer ribbon pushing the material from the two ends to the centre. Then, the inner ribbon pushes the material from the center to the two ends. To achieve material convention, the discharging port is fixed in the bottom centre. And then, with the help of the outer ribbon the material is discharged completely with no dead zone.

Under the drive of the motor, the double ribbon agitator mixes the material quickly. This ribbon mixer is characterized by high mixing effect, large productivity, and a very low failure rate. Since it is a batch type mixer, customers should choose the model according to the output per batch.

For Technical Parameters / Specifications, please download Ribbon Blender Mixer Technical Parameters / Specifications pdf

Note: Looking for something specific? Customisation is also available with above products. Please specify in the Enquire now page

*Prices shown above are provisional prices and may change due to different market conditions for latest prices please Contact Us at +91- 9820544120 or send enquiry through the Enquiry Form to get the final price within hours.

Applications of Ribbon Blender Mixer

Raymer Engineering Corporation Ribbon Blender Mixer is extensively used in paint manufacturing, coatings, inks, and other relevant industries. Ribbon Blender Mixers are mainly used in processing enamels, cement primers and emulsions. Beside this, our Ribbon Blender Mixer is utilized for processing a wide variety of products. Ribbon Blender Mixer can be used to mix powder with powder, powder with liquid, and powder with granule.

LET’S TALK ABOUT YOUR PROJECT

We would love to help you with your specialist application, enter your details below; we will

be in touch – no obligation.

About Raymer Engineering Corporation

Raymer Engineering Corporation was conceived in 1973. Since the foundation for meeting the requirements of paint dispersers and manufacturing machines, we have remained committed to fulfilling client’s requirements, while developing and sustaining long term relationships with honesty, integrity and respect. Through years of growth, dedication and innovation, we have registered a dominant position as one of the leading manufacturers, suppliers and exporters of Paint Manufacturing Machinery. With the strong support of skilled craftsmen and modern production technologies, we produce a broad spectrum of products such as Sand Mill, Ribbon Blender/Pug Mixer, Sigma Kneader, Twin Shaft Disperser, etc. Our business has experienced tremendous growth as we have continued to add new products and services to meet the demands of a rapidly expanding customer base.

Banking on the principles of continuous development and product improvement policies, we have consistently worked towards offering innovative products to clients. Moreover, continuous improvement of the quality system through continuous monitoring has enabled us to meet the changing needs of industry. Thus, with innovative production techniques and quality intensive applications, we have been able to cater to the process equipment needs of various industries including chemical manufacturing, glass and ceramics, etc., in the national as well as international markets.